By Dawn Wilson

3D printers are the next major technology item for many libraries. McGoogan currently has two printers, both from MakerBot: a 5th Generation single color printer and the double-extruder 2X model for printing two colors at once.

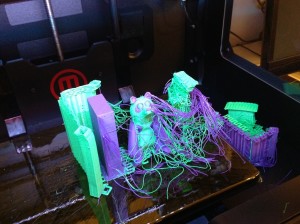

Requests are open to the UNMC and Nebraska Medicine, and we currently print objects for academic, clinical, and research use. As we’re still in the novelty and testing phase, we just never know how well the files are going to print! Just like a paper printer, some copies come out great and others are… not quite right. A lot depends on the file and type of printer it was designed for, but even more can be trial and error.

So how does it work (ideally)? Primarily, the files we use come from Thingiverse and Embodi, from Creative Commons files that other users have graciously uploaded. The printers use plastic filament (either PLA or ABS), which is colored and thicker than fishing line. The machine melts the filament and follows the pattern from the downloaded file, squirting a thin line of melted filament into a base and then the shape. When it comes to protrusions, the printer adds supports (to be removed later) to hold up sections that do not touch the build plate (such as the curved portion of a mandible). Inside, the honeycomb infill gives strength to the finished model.

So that’s how it’s supposed to work! But here are a few things we’ve learned along the way:

• PLA filament comes in a multitude of colors.

• ABS filament gives you a smoother build.

• Sorry, we cannot turn a photograph of your cat into a 3D print.

• 3D printers can jam, just like paper printers! If you catch it right away, you might be able to clear the jam and resume, otherwise you’ll end up with half a print. But the cool thing is that then you can see the inner workings of the build!

• It’s best to build on a raft so your print doesn’t fall over halfway through.

• Heated build plates bring their own list of problems when the models don’t want to stick.

• Large prints can take days. Our longest print took over three days.

Going into our third month, we’ve accepted 130 print jobs, most of which have been successful. Take a look at the photos to get an idea of the process!

For more information, see our 3D printing library guide.

- Evolution of a Panda

- Headless Beethoven

- Not Quite a Heart, Brain, or Foot

- A Little Trouble

- Close But No Cigar